Modified Polymer Technology Supports Development of Social Infrastructure

Roads

When making pavement for road work, only 5% of the mixture is asphalt, which is used to fix the sand and gravel ingredients. Since asphalt is thermoplastic, its viscosity decreases during formation of pavement (high temperature), and it mixes evenly with the sand and gravel to form a uniform surface, then becomes hard and durable with natural cooling. These qualities make it possible to build a strong road within a short construction period and asphalt is widely used worldwide.

However, as a result of global warming in recent years, a noticeable problem is that asphalt pavement can become indented due to the load of heavy vehicles such as trucks using the road in the summer.

Kao has designed a polymer that takes into account each component of pavement. With the use of only 1% asphalt pavement, a durability more than five times greater has been attained while maintaining good workability. In addition, a polymer has been designed that significantly improves the problems related to vulnerability to oil and rainwater.

Recently, Kao has successfully designed a polymer that can achieve the above-mentioned high durability performance while using recovered PET as a raw material. Along with the conclusion of verification testing, we are now proceeding with practical applications.

Through development of asphalt modified by polymers for use in pavement, Kao hopes to contribute not only to maintaining of cities where people can continue to live, but also a sense of responsibility for creating and using good roads.

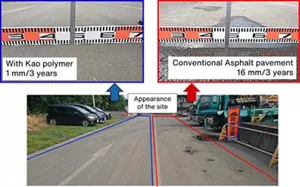

Comparison after 3 years of pavement asphalt in heavily trafficked areas and locations with frequent oil leaks.

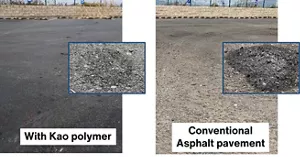

Comparison after 3 years of pavement in locations with frequent oil leaks

Related Information

- Home

- Innovation

- Research & Development

- Product Development Research

- Industrial Chemicals

- Modified Polymer Technology Supports Development of Social Infrastructure

- Home

- Innovation

- Research & Development

- Product Development Research

- Industrial Chemicals

- Modified Polymer Technology Supports Development of Social Infrastructure