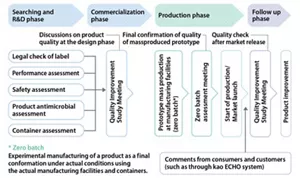

Quality Management Activities in Product Development, Production, and After Product Launch

Product Development Stage

We consider product safety, features and performance, product preservation characteristics, spoilage and mold resistance, and compliance with laws and regulations throughout the product development and commercialization stage in areas such as product formula and design, packaging design, and raw material selection. We also hold study meetings pertaining to product safety, preservation, and packaging, attended by people in divisions that handle respective products including those in consumer communication. The meetings result in consumer-driven product assessment and verification that envisages all stages of the consumer-product relationship from the consumer’s initial knowledge of a product, to product selection, purchase and take-home, as well as product use, storage, disposal, and refill.

Ultimately, following a series of product use tests under various conditions and evaluations by consumer monitors, we perform overall product evaluations at Quality Improvement Study Meetings to determine final product specifications.

Production Stage

Once we determine product specifications, we develop the required production technology while conducting repeated test production runs. Then, we move to the “zero-batch” testing production phase in which products are manufactured according to final product specifications using actual production facilities. Before we start commercial production for a given product, our research and development, and product technology divisions must first verify the quality of zero-batch prototypes, and moreover, all Kao divisions involved with the product must thoroughly evaluate and verify whether or not the product actually represents value to consumers/customers, and we must deem that no product issues need to be addressed.

Activities to Improve Product Quality Post-launch

Once products have been launched, staff from all company divisions use the Kao ECHO System on a daily basis to communicate with our consumers and respond to their concerns, inquiries and other feedback in a manner that achieves ongoing product improvements.

Quality Management Flow

We are building a traceability system able to trace aspects relating to product quality from raw materials to production, shipment, and logistics.

- Home

- Innovation

- Product Quality Management

- Quality Management Activities in Product Development, Production, and After Product Launch

- Home

- Innovation

- Product Quality Management

- Quality Management Activities in Product Development, Production, and After Product Launch