Development of Paper Pipe (EG Runner) Resistant to Heat Up to 1,400°C

Highly Heat-resistant Materials

Kao is focusing on renewable plant-derived pulp as an alternative to petroleum-derived plastic, and has developed a technology for forming paper bottles that place only a small burden on the environment when disposed of. In the process of creating the technology, we developed another one and applied it to a new field to produce EG Runner. This is a paper casting runner that resists temperatures as high as 1,400°C.

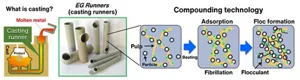

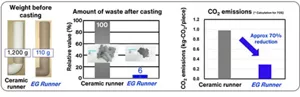

Casting is the processing method of pouring molten metal into a cast then cooling and hardening it. Generally, molten metal is poured into a cast through a ceramic runner, but ceramic runners are heavy and fragile, and generate a large amount of waste after casting.

By further refining technologies to form 3D structures as well as technologies for compounding functional materials accumulated in the development of paper bottles, we have been able to develop the pipe-shaped EG Runner by fixing resin that carbonizes and remains strong if exposed to high temperatures, heat-resistant inorganic particles, and other materials in the pulp.

EG Runner weighs approximately one tenth as much as a ceramic runner, reduces waste after casting by 94%, and reduces CO2 emissions by around 70%. This technology will enable us to contribute to the production of castings friendly to both people and the environment.

Awards Received Previously

Environmental Technology Prize of the 41st JCIA Technology Award received from the Japan Chemical Industry Association in May 2009

Minister of Economy, Trade and Industry Award: 16th Green and Sustainable Chemistry Award received from the Japan Association for Chemical Innovation in July 2019

Related Information

- Home

- Innovation

- Research & Development

- Product Development Research

- Industrial Chemicals

- Development of Paper Pipe (EG Runner) Resistant to Heat Up to 1,400°C

- Home

- Innovation

- Research & Development

- Product Development Research

- Industrial Chemicals

- Development of Paper Pipe (EG Runner) Resistant to Heat Up to 1,400°C