Development of Environmentally Friendly Cellulose Nanofiber Materials

Material Development

Cellulose nanofibers are tiny fibers (about 3 nm thick and several hundred nm to several microns long) produced by plants. Industry and society are eagerly awaiting new technologies and applications that can tap the potential of this “ultimate eco-material.”

Although not water soluble, cellulose nanofibers are highly hydrophilic. At Kao, we used sophisticated interface control to develop a technology for nano dispersion of these cellulose nanofibers even in a hydrophobic medium.

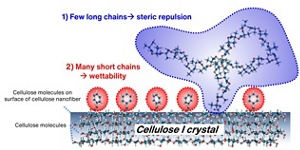

The key to the new technology is our technique of grafting two different modifying groups to the surface of cellulose nanofibers (Fig.1). The two modifying groups were selected on the basis of wettability and steric repulsion using computational chemistry. With this new approach to interface control, we were able to overcome obstacles that have daunted other researchers to achieve the elusive goal of isolated dispersion of nanofibers in a hydrophobic resin.

Fig.1 Double Graft System

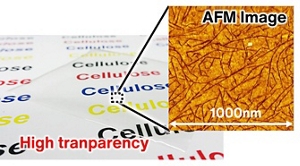

In addition, we succeeded in visualizing the dispersion of nanofibers by applying morphological analysis and found that they were forming a nano-network structure (Fig.2). This outcome made clear that the admixture of a very small quantity could impart special properties almost impossible to obtain with conventional reinforcing fillers, including high strength and toughness, low thermal expansion, and high transparency. We are currently evaluating the feasibility of various commercial applications.

Fig.2 Composite of Hydrophobic Resin and Cellulose Nanofibers

Kao will continue to pursue the development of groundbreaking composite materials that can contribute to a sustainable society.

Related Information

- Home

- Innovation

- Research & Development

- Product Development Research

- Industrial Chemicals

- Development of Environmentally Friendly Cellulose Nanofiber Materials

- Home

- Innovation

- Research & Development

- Product Development Research

- Industrial Chemicals

- Development of Environmentally Friendly Cellulose Nanofiber Materials