Resource Circulation Model Project for Material Recycling of Single-Use Plastic—Progress Made in Field Testing

Kao Corporation has been working together with other companies and organizations to realize a resource circulation model for material recycling*1 of single-use plastics. This project was launched in September 2020 after Kao was selected to participate in the New Business Model for Sustainable Use of Plastics initiative organized by the Tokyo Metropolitan Government. Even after the specified period for implementation of the initiative ended in February 2021, Kao has continued to implement this project in collaboration with Ichikawa Kankyo Engineering Co., Ltd., Ecomira Koto (operated by the NPO Chikyusen Club), and VIAX Co., Ltd. The progress made so far is outlined below.

-

* 1 Recycling of materials into products with the same application

Business enterprises chosen to participate in field testing for the New Business Model for Sustainable Use of Plastics initiative organized by the Tokyo Metropolitan Government

Purpose and Overview

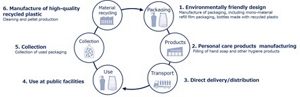

The aim of the project is to develop packaging that can be easily recycled, establish and put into use a resource circulation system for used packaging, and achieve social implementation.

●Design and manufacturing of bottle-type containers for hand soap that are made using recycled plastic, and refill packs made using monomer-material film

●Distributing empty bottle-type containers and refill packs in public facilities in Tokyo's Koto Ward, so that the bottle-type containers can be refilled, used, and then collected for recycling

●Implementing material recycling so that used refill packs that have been collected are used to make bottle-type containers

●Going forward, the aim is to achieve material recycling so that used refill packs can be recycled to make new refill packs

Design and manufacturing of bottle-type containers that are made using recycled plastic

●Bottle-type containers for hand soap have been designed and manufactured by Ichikawa Kankyo Engineering and Ecomira Koto.

●For hygiene reasons, the bottle-type containers have a multi-layer structure, with a layer of virgin material (polyethylene), then an adhesive layer, then a barrier layer, then an adhesive layer, then a layer of recycled material, and then a layer of virgin material (polyethylene), so that the content is in direct contact with virgin material.

●The recycled layer is based on recycled polystyrene derived from food trays that have been collected by Koto Ward and then sorted and pelletized by Ecomira Koto. To strengthen this layer, polyethylene PCR*2 material is used. The layer of recycled material accounts for around 50% of the total material in the bottle-type container.

●When using recycled material, the larger the size of the product, the more concerns there are regarding forming and product strength after forming, but this issue has been addressed through careful combination of raw materials, etc.

●Labels are displayed so that users are aware that these bottles were made using material derived from food trays collected in Koto Ward.

-

* 2 This includes waste material generated by households, as well as material deriving from products that end users such as commercial facilities, industrial facilities and other types of facilities can no longer use for their original intended purpose. It includes material returned via distribution channels.

Design and manufacturing of monomer-material refill packs

●Toppan Printing has designed and manufactured standing-type refill packs that can be filled with up to 400ml of hand soap.

●Olefin-based plastic film, which has superior heat seal properties, has been used. The container's sides and base are heat sealed.

●To ensure both the strength of the container seals and stable production, painstaking quality verification has been performed for each production process while adjusting factors such as temperature and time.

●The refill pack has been designed so that the spout can be cut out with scissors when refilling. The only items that are printed directly on the pack are the lines showing where to cut with scissors, and two marks required for manufacturing.

●Necessary information (including product use, composition, points to note, contact details, etc.) is displayed on the label. After collection for recycling, the label is removed and separated from the pack, so that the print material does not affect the quality (in terms of color and physical properties) of the refill pack recycled material.

Consumer survey

A consumer survey was conducted by the NPO GENKI Net for Creating a Sustainable Society to clarify the current state of refill pack usage, as well as how easy the new monomer-material refill packs are to use, and how willing consumers are to use them. Consumers were impressed by the fact that the new refill packs were transparent, by the simple design, and by how eco-friendly they are; the survey results thus confirmed that this type of design does have an environmentally-friendly image. On the other hand, there were comments to the effect that having to cut the spout open with scissors was inconvenient, and made refilling difficult; the results thus also indicated the need for a more user-friendly container design.

Distribution of bottle-type containers and refill packs to public facilities in Koto Ward, and collection of used products

●In early April 2021, a total of around 2,000 bottle-type containers and approximately 8,000 refill packs were distributed to municipal elementary and junior high schools, the Ward Office, and public sports and cultural facilities (for a combined total of around 90 facilities) in Tokyo's Koto Ward.

●After being used for a two-month period in April and May 2021, the products that had been provided were collected for recycling.

●The collected refill packs were sorted by Ecomira Koto, after which Ichikawa Kankyo Engineering carried out washing, pelletizing and forming to create new bottle-type containers.

●The exterior of the bottle-type containers was checked for damage etc.

Challenges and future development

●Production processes need to be improved in order to realize stable, continuous production of refill packs.

●In order to be able to supply monomer-material refill packs to stores, the refill packs will need to be able to keep their content in good condition for a longer period. There is a need for further technology development in regard to the materials and containers.

●After identifying the issues affecting each process, the project participants will continue to undertake R&D aimed at recycling collected refill packs into bottle-type containers.

The biggest challenge affecting plastic resource circulation is the need to balance the reduction of CO2 emissions with economic efficiency (in terms of functionality, cost, etc.). With this in mind, there is a need to develop low-cost, waste-free sorting and recovery systems, to develop precise classification methods for plastic packaging and to realize standardization of environmentally-friendly container design (with the formulation of the necessary standards and regulations). Going forward, the project participants will proceed with the development of resource circulation systems, and will be contributing toward the building of sustainable resource circulation in society.

Initiatives for Kao's ESG Strategy, the Kirei Lifestyle Plan and plastic circularity in society

Recognizing its responsibility as an enterprise that provides products which people use on a regular basis in their daily lives, Kao takes active steps to reduce the environmental footprint of its products throughout the entirety of the product lifecycle. In April 2019, Kao launched the Kirei Lifestyle Plan, its ESG (environmental, social and governance) strategy, which incorporates 19 key leadership actions. Kao's purpose is to create a Kirei life for all. The Japanese word 'kirei' describes something that is both clean and beautiful. For Kao, Kirei not only encapsulates appearance, but also attitude—to create beauty for oneself, other people, and for the world around us. The Kirei Lifestyle Plan aims to integrate ESG as the foundation of its management to accelerate business growth and create products and services of better value for consumers and society.

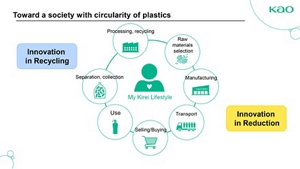

Regarding the issue of plastic waste, which is a significant problem for society, in 2018, Kao announced its "Our Philosophy & Action on Plastic Packaging" declaration, and are abiding by the 4Rs: Reduce, Replace, Reuse, Recycle. We are substantially reducing the amount of plastic used in our packaging, by making them thinner, reusable, refillable, and reduced in volume, as well as improving our liquid concentration. We are also developing packaging that is easier to recycle. Plus, we will make efforts to switch away from fossil fuel-based plastics toward the use of sustainable materials.

In September 2019, Kao announced that it would be focusing on Innovation in Reduction and Innovation in Recycling, so as to help realize a society characterized by effective plastic resource circulation. In the area of Innovation in Recycling, we are collaborating with other companies and organizations on the horizontal recycling of plastic packaging. Initiatives for which we are undertaking verification testing include the recycling of film packaging made using multiple different materials, which in the past has been considered difficult to recycle, as well as recycling of mono-material film packaging (which is made using a single material), and of mono-material bottle containers. We are also conducting demonstration testing for many other projects, including recycling of items other than packaging, such as used diapers.

By integrating ESG into the core of its company management, Kao will drive business growth and better serve consumers and society through its enhanced products and services. With this socially conscious ethos, Kao will create a Kirei life for all—providing care and enrichment for the life of all people and the planet.

-

* This news release is a translation of a Japanese-language news release dated October 28, 2021.

About the Kirei Lifestyle Plan

Over the past 130 years, Kao has worked to improve people's lives and help them realize more sustainable lifestyles—a Kirei Lifestyle. The Japanese word 'kirei' describes something that is clean, well-ordered and beautiful, all at the same time. The Kao Group established its ESG strategy, the Kirei Lifestyle Plan in April 2019, which is designed to deliver the vision of a gentler and more sustainable way of living. By 2030, Kao aims to empower at least 1 billion people, to enjoy more beautiful lives and have 100% of its products leave a full lifecycle environmental footprint that science says our natural world can safely absorb.

For more information please, click

About Kao

Kao creates high-value-added products that enrich the lives of consumers around the world. Through its portfolio of over 20 leading brands such as Attack, Bioré, Goldwell, Jergens, John Frieda, Kanebo, Laurier, Merries, and Molton Brown, Kao is part of the everyday lives of people in Asia, Oceania, North America, and Europe. Combined with its chemical division, which contributes to a wide range of industries, Kao generates about 1,400 billion yen in annual sales. Kao employs about 33,000 people worldwide and has 130 years of history in innovation. Please visit the Kao Group website for updated information.

Media inquiries should be directed to:

Corporate Strategy

Kao Corporation