Kao Starts Demonstration of Resource Circulation Model Project for Material Recycling of Single-Use Plastic

Kao selected as a business operator in the New Business Model for Sustainable Use of Plastics initiative of the Tokyo Metropolitan Government

Kao Corporation has been selected from among applicants to be a business operator in the New Business Model for Sustainable Use of Plastics initiative organized by the Tokyo Metropolitan Government. Together with other participating companies and groups, Kao will take part in a resource circulation model project for material recycling*1 of single-use plastic.

-

* 1 Recycling of materials into products with the same application

Since the 1990s, Kao has been taking steps to reduce the amount of plastic used in its packaging, by making products more highly concentrated to make packaging more compact and by developing and promoting the use of refill and replacement products. On the other hand, besides PET bottles used for beverages, recycling of other plastics including the plastics in product packaging has not made much progress. Much of this plastic is so-called single-use plastic and gets incinerated with energy recovery or ends up simply incinerated, in landfills, or exported overseas. After China restricted the import of waste plastics, resulting in restrictions on the export of plastics overseas, needs for domestic processing of these other plastics exceeded capacity. In addition, the need to combat marine plastic waste also necessitates a system for domestic resource circulation of these other plastics.

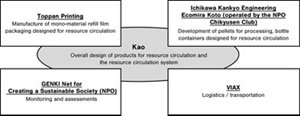

Therefore, as a manufacturer of consumer products Kao is playing a leading role in a resource circulation project aimed at material recycling of single-use plastics that effectively uses resources and minimizes waste to help realize a sustainable society. The project involves cross-industry cooperation with a value chain comprising Toppan Printing, which develops environmentally friendly products in a wide range of fields, Ichikawa Kankyo Engineering and Ecomira Koto (operated by the NPO Chikyusen Club), which are engaged in domestic resource circulation in Japan, GENKI Net for Creating a Sustainable Society (nonprofit organization), which is conducting monitoring and assessments with consumers, and VIAX, which plans the proactive use of circulation-type products in its mail-order business. The project involves the development of actual refill film packaging made with mono-materials, tack labels that can be easily peeled off (to avoid plastic contamination from direct printing), and bottle containers made with recycled plastic. In addition, the project aims to establish and put into use a resource circulation system including collection of used packaging.

Currently in Koto-ku (Tokyo), polystyrene food packaging (trays and so on) is collected separately after being cleaned by residents. Foreign substances are then removed from the food packaging by Ecomira Koto, a facility located in Koto-ku, and it is processed into highly pure plastic pellets. This system will be employed to make pellets from the used packaging collected in the model project.

Yoshihiro Hasebe, Representative Director, Senior Managing Executive Officer and Senior Vice President of Global Research and Development, Kao, commented on the project as follows. "To effectively solve the problem of single-use plastics, one of the most critical issues involving plastic waste, a platform needs to be created that allows more companies in the product value chain to easily participate. Kao and the companies and groups participating in this model project will actively promote the project and urge others to get involved in CLOMA (Japan Clean Ocean Material Alliance),*2 aiming to gain the understanding and cooperation of many different stakeholders and advance the project as a society-wide initiative. Additionally, we are aiming to promote this project to the world as a new solution for plastic waste from Japan that leads to the creation of resource circulation in society."

-

* 2 A platform to accelerate innovation and strengthen cooperation among a wide range of players across industries to solve the problem of marine plastic waste, which has emerged as a global environmental issue

Overview of the resource circulation model project for material recycling of single-use plastic

Project description

Plastic packaging for personal care products will use mono-materials or recycled plastics. The project aims to use advanced recycling technology, packaging design and manufacturing technology to recycle single-use packaging materials. During the period of this demonstration experiment, bottle container prototypes using recycled plastic and mono-material refill film packaging prototypes will be created and distributed to public facilities in Koto-ku, Tokyo.

After the demonstration period as well, the used refill film packaging will be collected, cleaned and made into pellets, and Kao will continue making bottle prototypes with the recycled plastic created from these pellets. In the future, Kao aims to achieve material recycling that recycles refill film packaging into new refill film packaging.

Project period

September, 2020 - February, 2021

Participating companies / groups

Toppan Printing

Ichikawa Kankyo Engineering

Ecomira Koto (operated by the NPO Chikyusen Club)

GENKI Net for Creating a Sustainable Society (NPO)

VIAX

* CLOMA*2 member companies will participate as necessary.

Roles of participating companies / groups

1. Kao, as a manufacturer of daily necessities, will perform the overall design of products for resource circulation and the resource circulation system

2. Toppan Printing will manufacture mono-material refill film packaging designed for resource circulation

3. Ichikawa Kankyo Engineering (and its partner companies) and Ecomira Koto (operated by the NPO Chikyusen Club) will develop recycled pellets able to be easily processed and bottle containers designed for resource circulation using the pellets

4. GENKI Net for Creating a Sustainable Society (NPO) will conduct monitoring and assessments with consumers

5. VIAX, using the logistics network of its mail-order business, will deliver the trial products to public facilities in Koto-ku (Tokyo)

Initiatives for Kao's ESG Strategy, the Kirei Lifestyle Plan and plastic circularity in society

Recognizing its responsibility as an enterprise that provides products which people use on a regular basis in their daily lives, the Kao Group takes active steps to reduce the environmental footprint of its products throughout the entirety of the product lifecycle. In April 2019, Kao launched the Kirei Lifestyle Plan, its ESG (environmental, social and governance) strategy, which incorporates 19 key leadership actions. Kao is now beginning the full implementation of related activities by enhancing its core value of Yoki-Monozukuri that it has built up through its corporate activities to realize "Yoki-Monozukuri with ESG integration (ESG-driven Yoki-Monozukuri)." Kao defines Yoki-Monozukuri as a strong commitment by all members to provide products and brands of excellent value for consumer satisfaction. It plans to further strengthen its initiatives incorporating environmental and social considerations.

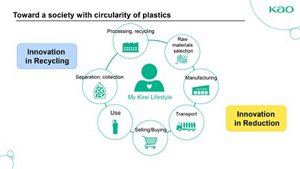

Regarding the issue of plastic waste, which is a significant problem for society, Kao has for some time now been contributing towards the resolution of this issue by making the material used for plastic containers thinner, promoting the use of refill packs, making products more highly concentrated, and shifting over to larger-sized containers, etc. In 2018, Kao released "Our Philosophy & Action on Plastic Packaging," which details its approach to plastic packaging. In addition, in September 2019, Kao announced that it would be focusing on Innovation in Reduction and Innovation in Recycling, so as to help realize a society characterized by effective plastic resource circulation.

In the future, the Kao Group will continue to implement its unique ESG activities globally, so as to deliver satisfaction and enriched lives for people around the world, and contribute to the sustainability of society.

About Kao

Kao creates high-value-added products that enrich the lives of consumers around the world. Through its portfolio of over 20 leading brands such as Attack, Bioré, Goldwell, Jergens, John Frieda, Kanebo, Laurier, Merries and Molton Brown, Kao is part of the everyday lives of people in Asia, Oceania, North America and Europe. Combined with its chemical division, which contributes to a wide range of industries, Kao generates about 1,500 billion yen in annual sales. Kao employs about 33,000 people worldwide and has 130 years of history in innovation. Please visit the Kao Group website for updated information.

Media inquiries should be directed to:

Corporate Communications

Kao Corporation