Analysis Technologies that Ensure Reliable Container Quality

Environmental Science

Various kinds of containers are used for Kao’s products.

All these containers are required to have moderate strength to withstand grasping when in use, buckling strength and drop impact strength to prevent distortion during transportation and storage, and other kinds of strength. While environmentally friendly containers must be thinner and smaller than ever before, making containers thinner alone compromises their strength.

In an initiative to solve this problem, we decide on optimal container shapes by analyzing the strength of containers using the finite element method in all container design stages ranging from initial design to design for actual production. We also simulate and analyze changes in fluid in containers and its flow volumes and speeds when they are in use in order to explore user-friendly container shapes.

After these precise tests, we can produce high-performance containers optimized in terms of resin types, volumes, and shapes.

In research on packaging technologies, we also do thorough follow-up for designed containers to check whether their shapes are as designed whether they contain defects.

For example, containers used for pump-type shampoos or spray-on bathroom detergents are called dispenser containers, and have complicated mechanisms comprising a lot of parts. These containers, where different parts are combined to express a single function, embody analysis technologies, including analysis to check the fit between different parts such as bottles and caps or dynamic analysis to check pump operations, as basic element technologies that support container quality.

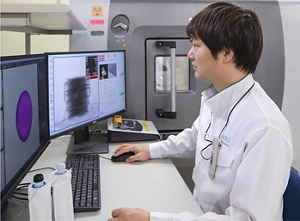

Kao takes advantage of dynamic X-ray observation to check the movements of parts or the flow of fluid in containers in real-time. We also use equipment for X-ray CT observation to clearly observe the fit between parts, and to spot defects and other conditions non-destructively in order to improve container quality.

Observation of a container using

equipment for X-ray CT observation

- Home

- Innovation

- Research & Development

- Fundamental Research

- Packaging Technology

- Analysis Technologies that Ensure Reliable Container Quality

- Home

- Innovation

- Research & Development

- Fundamental Research

- Packaging Technology

- Analysis Technologies that Ensure Reliable Container Quality