Research & Development

Kao undertakes research that contributes towards the sustainable development of society and enriches the lives of people throughout the world. We aim to develop a scientific understanding of the essential nature of phenomena, and we generate new value through matrix management of product development research and fundamental research.

R&D Philosophy

Kao’s corporate philosophy, “The Kao Way,” defines Kao’s mission as “to strive with enthusiasm and unity of purpose to enrich people’s lives every day, to create the Kirei Life, and to share joy through innovation to create superior value, and to realize a safe and harmonious world for all life”.

“Kirei” is not just about appearance. In Japanese, the word “Kirei” means cleanliness, order, beauty, and everything in between. It is a value that describes a way of life that seeks to create beauty for oneself, for others, and for the natural world around us.

In order to realize the Kirei Life, the R&D Division will devote all its efforts to Yoki-Monozukuri, which meets the present and future needs of people, society, and the Earth. “Yoki-Monozukuri” means deeply understanding the needs and values of consumers and customers, and providing high-value products, brands, technologies, and solutions that truly satisfy consumers and customers around the world. In order to continuously create innovative value, we want to combine the creativity and vitality of all our employees and teams to take on the challenge of new science and technology.

We will continue to boldly take on the challenges of the future.

Research Field

Creating Innovative Products through the Integration of Science and Technology

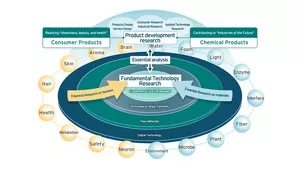

Kao’s research and development activities are characterized by the integration of science and technology spanning a wide variety of fields.

The overall framework of our business activities is expressed in the slogan, “Cleanliness, Beauty, and Health Every Day.” To achieve these goals, our R&D Division creates innovative products by integrating two kinds of research: product development research, which is dedicated to designing and commercializing products that meet consumer needs; and fundamental technology research, which is dedicated to deepening our understanding of the materials, mechanisms, and phenomena we encounter. This integration enables us to create innovative products that can be used by people all over the world.

Our first step in designing a product (our product development research) is to thoroughly understand their lives and needs of our consumers on a global scale. From this starting point, we pursue product design and application technology development that coalesces into products that give people enjoyment and satisfaction.

In our fundamental technology research, we investigate the truth behind the various phenomena by utilizing advanced science and technology in various fields, including chemistry, physics, and biology. Fundamental technology research plays a crucial role in the development of products with true value.

Our pursuit of Yoki-Monozukuri begins through integration of various research fields such as fat and oil science and surface science, which are the starting points for our businesses and production engineering fields. To this is added consideration of emotional value, as well as research on quality, safety, and environmental compatibility.

Products with true value cannot be created through work in a single scientific or technical field. Through a cross-industrial and interdisciplinary approach that transcends existing academic frameworks, we pursue new sciences and technologies that can open the door to the future.

Kao’s R&D/Fusion of Science and Technology

Kao’s R&D Activities

Product Development Research

Kao promotes R&D efforts in product design and applied technology along with consumer research, helping us achieve a deep understanding of the needs and lifestyles of global consumers.

Fundamental Research

Kao conducts research that identifies the structure of phenomena and substances in various fields in order to make truly valuable products.

R&D Basic Information

-

Management

Within an open corporate culture which respects the autonomy of researchers, we employ matrix management that encourages the dynamic sharing of knowledge from many different fields.

-

Global Network

With the expansion of global business, Kao has been actively promoting R&D efforts based on Yoki-Monozukuri in Asia, the Americas, and Europe. Here is an introduction to our major activities and global network.

-

Awards

List of major research topics awarded

-

Publications

List of major scientific research publications