Kao Corporation Odawara Plant Introduces New Production System for Efficient High-Mix Low-Volume Manufacturing

Innovative Dynamic Cell Production Operations Begin, Solving Productivity and Flexibility Challenges

Kao Corporation has developed a dynamic cell production system that enables efficient high-mix low-volume manufacturing in collaboration with B&R K.K. and Kyoto Seisakusho Co., Ltd. and recently introduced it at the Odawara Plant (Kao Cosmetics Products Odawara) in Kanagawa Prefecture, which is the Kao Group’s global cosmetics supply base.

Test operations will be finished by the end of 2023, and operations will begin in stages beginning in early 2024 for the production of cosmetics, which frequently involve small quantities and a wide range of products. Simultaneously, Kao will develop material supply automation and aims to establish technology as soon as possible.

Features of Dynamic Cell Production System

Odawara Plant’s dynamic cell production system for cosmetics

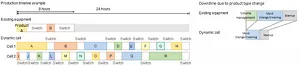

Dynamic cell production system operation example

The dynamic cell production system combines floating linear transport technology*1 and robot technology to freely transport and process each product individually, allowing products with different processes and processing times to be put and produced on the same production line at the same time. In addition, advanced automation technology enables operation with a minimal number of personnel and rapidly changing production varieties, Kao can make products that meet the diverse needs of consumers, when and in the amount required, without waste, achieving efficient high-mix, low-volume manufacturing.

-

* 1 Floating linear transport technology:

A linear transport system that allows objects with built-in permanent magnets to float and move freely by controlling the repulsive or attractive magnetic force. With this system, high-speed, high-precision and complex transfers are possible. Floating linear technology facilitates both flexibility and efficiency in production.

The newly installed equipment is capable of producing two types of products at the same time and can be operated by one person, making it easier to secure personnel, and the capacity of 24-hour production with shift operation is estimated to be about nine times higher than the existing equipment’s 8-hour production. Furthermore, the time necessary to switch types of products is predicted to be decreased by around 60%. Kao aims to improve productivity and cost efficiency, address labor shortages, a declining birthrate and an aging population, and improve the working environment and job satisfaction, with advancing automation further in the future.

Improving productivity with dynamic cell production system

Kao will continue to focus on further integration of smart features in the supply chain by actively utilizing cutting-edge technology and promoting DX through co-creation with exceptional partners. By disseminating new manufacturing ideas and technologies, Kao aims to realize a sustainable supply chain by encouraging open innovation to solve social issues in collaboration with a wide range of various manufacturers and others.

The Supply Chain Kao Aspires for

With the corporate purpose “to realize a Kirei World in which all life lives in harmony,” Kao Group established its ESG strategy, the Kirei Lifestyle Plan in 2019, and since 2021, has been employing the Kao Group Mid-term Plan with its vision of “protecting future lives” and “sustainability as the only path.”

Kao is promoting Yoki-Monozukuri*2 with ESG integration which preserves resources and reduces the burden on the environment, and is working to help people live richer lives and create a caring and resource-circulating society that develops sustainably.

By utilizing rapidly evolving digital technology and collaborating with various partners, Kao aims to develop innovative technology and build a sustainable supply chain that meets the expectations of society and is kind to people, society and the Earth.

-

* 2 Kao defines Yoki-Monozukuri as a strong commitment by all members to provide products and brands of excellent value for consumer satisfaction.

About Kao

Kao creates high-value-added products and services that provide care and enrichment for the life of all people and the planet. Through its portfolio of over 20 leading brands such as Attack, Bioré, Goldwell, Jergens, John Frieda, Kanebo, Laurier, Merries, and Molton Brown, Kao is part of the everyday lives of people in Asia, Oceania, North America, and Europe. Combined with its chemical business, which contributes to a wide range of industries, Kao generates about 1,550 billion yen in annual sales. Kao employs about 35,400 people worldwide and has 136 years of history in innovation. Please visit the Kao Group website for updated information.

Media inquiries should be directed to:

Public Relations

Kao Corporation