Fine Fiber Technology with Base Makeup:

Base Makeup Applied to Fine Fiber Membrane Results in Film that Smooths Skin Roughness and Gives High Spot-covering Effect

The Makeup Research Laboratory, Skin Care Research Laboratory, and Analytical Science Laboratory of Kao Corporation (President: Michitaka Sawada) discovered that base makeup applied with "Fine Fiber Technology", which creates a light, soft, and natural layered ultra-thin membrane by spraying submicron fibers directly onto the skin surface, resulted in smoothened skin irregularities, providing coverage of spots naturally and beautifully.

The results of this study were presented at the 71st Divisional Meeting of the Division of Colloid and Surface Chemistry (September 14-16, 2020, online) and received the Best Online Presentation Award. The findings were also presented at the 25th JFACE (Japanese Academy of Facial Studies) Annual Conference (October 3-4, 2020, online).

Background

Smooth skin free from spots and an uneven tone is what many women look for when using base makeup. But when they try to cover those with a base makeup cosmetic, they often feel that it is too heavy or does not cover spots well. In 2018, researchers at Kao reported that areas with spots are different from other areas, not only in regard to color but also the morphology of skin grooves, thus application of a base makeup formulation often leads to uneven results.*1

To provide a method for covering spots on skin beautifully, Kao has focused on use of fine fiber technology to form an ultra-thin membrane for producing uniform skin surface texture and shape.

After spraying the ultra-thin fine fiber onto skin, a cosmetic preparation is applied to it, which makes a transparent membrane that becomes integrated with the skin. This study examined in detail the structure of the coating film formed by layering a base makeup cosmetic preparation on top of that integrated membrane as well as it effects to conceal stains.

-

* 1 Kao news release in 2018 (in Japanese):

https://www.kao.com/jp/corporate/news/rd/2018/20181226-001/

Characteristics of film formed by fine fiber membrane and base makeup

1. The fine fiber membrane was found to evenly retain the base makeup powder, demonstrating a good covering effect

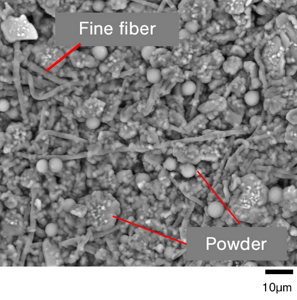

An ultra-thin fine fiber membrane was prepared on an artificial skin model with an uneven surface, then a base makeup formulation was applied to it. The resultant coating film was then observed by SEM. It was revealed that the fine fiber membrane had a three-dimensional structure consisting of interfolded superfine fibers with a large number of small gaps between them. When applied, the powder contained in the base makeup formulation was laid over evenly and densely, and became fixed in the gaps (Figure 1). By use of this fine fiber membrane, a high covering effect can be achieved, even with a small amount of base makeup formulation.

Figure 1. Powder contained in base makeup formulation evenly retained in fine fiber membrane

2. Cosmetic film makes skin texture smooth by covering uneven surface

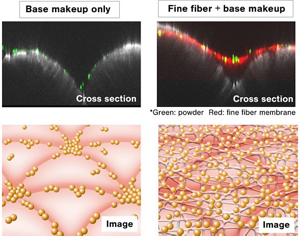

A fine fiber membrane made from ultrafine fibers dyed red was formed on the model skin, then a base makeup formulation containing cosmetic powder that emits green fluorescence was applied and observations were performed with fluorescent microscopy. Those findings showed that the film covered depressions, such as skin grooves and pores, and functioned as a bridge to hold the powder in the gaps (Figure 2).

As a result, when base makeup is applied to the fine fiber membrane, a coating film like a soft hammock is formed, which covers skin irregularities and keeps the powder from falling into skin grooves, providing a smooth appearance.

Figure 2. Retention of powder in base makeup formulation by fine fiber membrane to cover skin irregularities

Spot covering effect of base makeup layered on fine fiber membrane

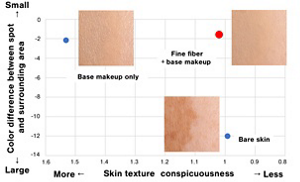

When a base makeup cosmetic was applied onto the fine fiber membrane, spot boundaries became less conspicuous as compared to use of a base makeup formulation alone (Figure 3).

Figure 3. Makeup finish. Final appearance as result of spot coverage

Furthermore, color brightness and texture were compared among bare skin, skin with only a base makeup formulation applied, and skin with the base makeup formulation applied onto a fine fiber membrane*2 (Figure 4). With only the base makeup formulation, the difference in color between spots and surrounding areas was inconspicuous, while skin texture was more noticeable as compared to bare skin. This was because the base makeup accumulated in skin grooves, resulting in a large difference in amount of adhesion between the sulcus cutis and crista cutis associated with skin texture, causing an unevenness in the base makeup.

On the other hand, there was no noticeable difference in color or texture of the coating film when the base makeup was layered on the fine fiber membrane. This is considered to be because the membrane not only retains the base makeup powder uniformly but also conceals skin irregularities, thus negating differences in color and skin groove shape between spots and other areas.

-

* 2 Difference in color between spots and surrounding area: Obtained by calculation of color lightness.

Texture conspicuousness: Skin roughness corresponding to texture was determined by multiresolution analysis (method for resolving components related to roughness shown in images by size).

Figure 4. Differences in color brightness and texture conspicuousness of spots

Conclusion

In this study, Kao researchers found that a smooth skin appearance can be obtained by overlaying base makeup onto a fine fiber membrane, as the base makeup powder was shown to be evenly retained by the film to improve skin irregularities. This makes it possible to beautifully cover spots that conventional base makeup cosmetics do not conceal well. Kao intends to continue developing products that meet the needs of its customers.

About Kao

Kao creates high-value-added products that enrich the lives of consumers around the world. Through its portfolio of over 20 leading brands such as Attack, Bioré, Goldwell, Jergens, John Frieda, Kanebo, Laurier, Merries and Molton Brown, Kao is part of the everyday lives of people in Asia, Oceania, North America and Europe. Combined with its chemical division, which contributes to a wide range of industries, Kao generates about 1,500 billion yen in annual sales. Kao employs about 33,000 people worldwide and has 130 years of history in innovation. Please visit the Kao Group website for updated information.

Media inquiries should be directed to:

Corporate Communications

Kao Corporation