High-Performance Cellulose Nanofiber Composite Resin"LUNAFLEX" with Unique Hydrophobization Technology

This is an English translation of reference material released in Japanese on June 5.

Kao Corporation (President: Michitaka Sawada) has successfully modified biomass-derived cellulose nanofiber (CNF) and blended that with resins for various applications, with results showing increased strength and dimensional stability (decreased thermal expansion rate) even in small amounts. Kao has begun offering modified CNF-formulated high-performance resin as the "LUNAFLEX" series, which can be customized according to the purpose or application of the user.

Improvements in physical properties gained by blending modified CNF contribute greatly to reduced resin usage, thus achieving downsizing and weight reduction. Kao believes this product will make meaningful contributions to efficient resource utilization and the sustainability of society.

Background

CNF forms bundles of cellulose molecules in plants such as trees and has been anticipated to be effectively utilized worldwide as a sustainable high-performance material with various advantages, such as high strength and elasticity. It has been shown that blending CNF with various types of resins increases their strength and toughness, as well as dimension stability.

However, because CNF is held together tightly by hydrogen bonding between and within molecules, it was a difficult challenge to isolate the nanofibers, as that required unraveling one by one. Furthermore, even following isolation, the surface remains covered by a hydroxyl group and is strongly hydrophilic, thus does not mix well with oily solvents, making dispersion stabilization difficult to obtain.

Conventionally, CNF preparations (hydrophobic modified CNF and CNF dispersion solvent) produced by CNF manufacturers are provided to users for resin production. However, problems such as CNF aggregation when mixing with resin often occur, which indicates that expertise is required for uniform nano dispersion in resin.

Introduction of "LUNAFLEX"

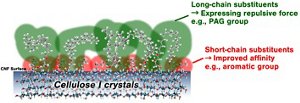

Kao researchers have successfully employed a CNF isolation method developed by Professor Akira Isogai of Tokyo University*1 , a leading expert in cellulose research. Using that, a technique that includes addition of various functional groups to the CNF surface based on Kao's uniquely accumulated interface control technique has been developed. The result is modification of the hydrophilic CNF surface to one that is hydrophobic, resulting in uniform nano dispersion of CNF in resin. This technology involving interface control for CNF surface design is called the "Dual Graft System" (Fig. 1). It is based on structural forecasting by quantum chemical calculation. With this method, 2 types of modification groups, selected in view of wettability and steric repulsion, are bound on the CNF surface. Modification of the hydrophilic CNF surface to a hydrophobic surface is accomplished by utilizing the low weight of the modification group and development of CNF intrinsic physical properties. In addition, customization of the appropriate modification groups in terms of wettability and steric repulsion makes it compatible for mixing CNF with resin.

-

* 1 T. Saito, A. Isogai et. al., Biomacromolecules. 2006, 7, 1687-1691.

Fig. 1. Dual graft system (model diagram) wetting and natural drying

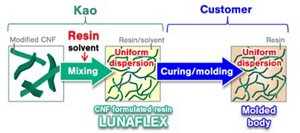

By uniform distribution of CNF in various types of resin, high-performance composite resins that maximize the performance of CNF have been developed and are now available for resin manufacturers. In addition to providing these complex materials, Kao has begun to offer problem-solving modified CNF formulated resins to resin manufacturers. This is called the "LUNAFELEX" series (Fig. 2).

Fig. 2. Problem-solving modified CNF formulated resin "LUNAFLEX" series

Examples of "LUNAFLEX" series (samples of customization with modified CNF for resin blending)

(1) Application to photocurable (acrylic) resin

Figure 3 shows a sample in which modified CNF was mixed with photocurable (acrylic) resin and a molded body, as well as an image taken with atomic force microscopy (AFM). Modified CNF formulated products are expected to be utilized for various applications due to uniform dispersion in resin and remarkably high transparency.

Fig. 3. Acrylic resin blended with modified CNF (fluid) and its molded product (transparent film), and image obtained with AFM (CNF 10wt% blended)

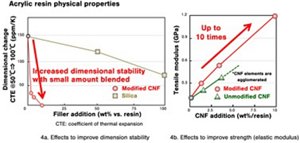

It has been confirmed that the physical properties provide effects to increase dimension stability with a very small amount of modified CNF as compared to a product blended with silica (all-purpose filler) for resin reinforcement (Fig. 4a). Furthermore, with greater amounts of CNF added, strength (elastic modulus) is increased by up to 10 times (Fig. 4b).

Fig. 4. Effects of adding CNF to photocurable resin (acrylic resin)

(2) Application to thermosetting (epoxy) resin

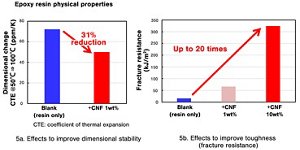

Figure 5a presents physical property data from samples of thermosetting resin blended with modified CNF. Those indicate that a product blended with 1% CNF had a dimensional change reduction of 31% as compared to a blank product without modified CNF. In addition, toughness increased as more CNF was added, with fracture resistance improved by up to 20 times (Fig. 5b).

Fig. 5. Effects of CNF addition to thermosetting (epoxy) resin

(3) Application to thermoplastic (phenoxy) resin

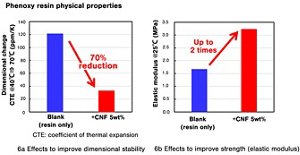

Dimensional change was suppressed by 70% (Fig. 6a) when 5% modified CNF was blended with phenoxy resin, a thermoplastic type, while strength (elastic modulus) was doubled (Fig. 6b).

Fig. 6. Effects of CNF addition to thermoplastic (phenoxy) resin

Future outlook

Following surface modification, modified CNF with high levels of dispersion and mixability with resins can be blended with photocurable acrylic, thermosetting epoxy, and thermoplastic phenoxy resins. The result is remarkable increases in physical properties. Kao will continue to develop new products with improved performance for effective use of modified CNF for various resins and user applications.

With an environmental, social, and governance (ESG) perspective, the Kao group will employ global development of unique ESG activities with the aim of contributing to the sustainability of society. The chemical business department will continue efforts to solve problems faced by our customers as well as members of industry throughout the world by providing chemical products with an eco-chemical perspective.

About Kao

Kao creates high-value-added products that enrich the lives of consumers around the world. Through its portfolio of over 20 leading brands such as Attack, Bioré, Goldwell, Jergens, John Frieda, Kanebo, Laurier, Merries and Molton Brown, Kao is part of the everyday lives of people in Asia, Oceania, North America and Europe. Combined with its chemical division, which contributes to a wide range of industries, Kao generates about 1,500 billion yen in annual sales. Kao employs about 33,000 people worldwide and has 130 years of history in innovation. Please visit the Kao Group website for updated information.

Media inquiries should be directed to:

Corporate Communications

Kao Corporation