Biorefinery Research Contributing to “Kirei Life for People, Society, and the Planet”

Microbiology

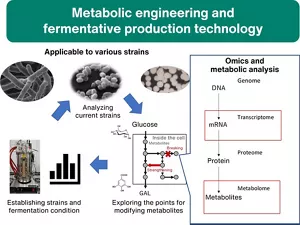

Nowadays most chemical raw materials are chemically synthesized from petroleum or extracted from plants. But a new manufacturing process has entered the spotlight: biorefinery, which uses fermentative production technology.

Aromatic compounds, a group of industrially valuable chemical raw materials, present environmental problems because they are derived from petroleum. In addition, their supply chain is vulnerable because they depend on natural resources. However, commercial fermentative production of these compounds has been limited to date due to many complicated steps in the metabolic pathways inside microorganisms.

To overcome this problem, Kao has focused on coryneform bacteria, which are reportedly resistant to aromatic compounds, and successfully introduced carefully designed modification of the metabolic pathways and suppressed metabolic pathways that produce by-products.

With these outcomes, we have established a highly efficient technique to fermentatively produce gallic acid*1 , one of the aromatic compounds, from glucose, a sustainable ingredient. Furthermore, we have induced our proprietary metabolic enzymes into coryneform bacteria and successfully constructed a biosynthetic pathway of aminophenol derivatives, which will be ingredients of engineering plastics*2 .

From here, Kao will comprehensively apply metabolic- and enzyme-engineering technologies and help to bring about a biorefinery-based, sustainable society.

-

* 1 The substance to be used as, for example, a raw material for semiconductor manufacturing

2024/01/11 News release

Launch of Bio Aromatic Compound ‘Gallic Acid’ through Fermentation Production*1 Stable Supply of Industrial Essential Chemical Materials -

* 2 Nonaka, K., Osamura, T., Takahashi, F. (2023). A 4-hydroxybenzoate 3-hydroxylase mutant enables 4-amino-3-hydroxybenzoic acid production from glucose in Corynebacterium glutamicum. Microbial Cell Factories, 22(168), 1-16.

Related Information

- Home

- Innovation

- Research & Development

- Fundamental Research

- Biological Science

- Biorefinery Research Contributing to “Kirei Life for People, Society, and the Planet”

- Home

- Innovation

- Research & Development

- Fundamental Research

- Biological Science

- Biorefinery Research Contributing to “Kirei Life for People, Society, and the Planet”