Kao Has Developed Fine Fiber Technology That Creates a Layered, Ultra-thin membrane Made from Submicron Fibers, Contributing to the Cosmetic and Therapeutic Fields

Kao Corporation has announced the development of fine fiber technology. Fine fiber technology creates a light, soft, and natural ultra-thin membrane on the surface of the skin. This film is formed by directly spraying the skin with superfine fibers just submicrons in diameter.

By using fine fiber technology in combination with various Kao-developed products, it is now possible to go beyond traditional concepts in cosmetic fields such as skincare and makeup. With an eye on applications in the therapeutic field in the future, Kao is advancing related research. Arrangements are being made to present the results at academic conferences, such as those focusing on fiber engineering, dermatology, or cosmetics science.

What is fine fiber technology?

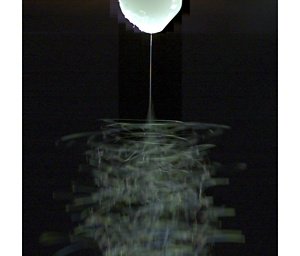

Fine fiber technology enables a layered, ultra-thin membrane made of superfine fiber to form on the surface of the skin. The membrane is created by spraying the skin directly with a polymer solution developed for cosmetics. The solution is loaded into a small, specialized applicator and discharged through a nozzle. With this technology, anyone can easily form a film that is molded to the three-dimensional shapes and areas of various parts of the body.

Potential of fine fiber technology

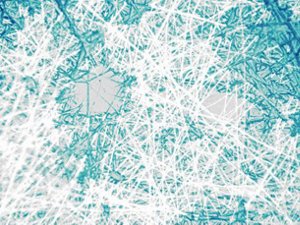

A model liquid solution (blue) spreading throughout the layered, ultra-thin membrane

The layered, ultra-thin membrane created via fine fiber technology is light, soft, and natural. It also moves flexibly with the skin while making the surface even and smooth. The film's greatest feature is its outstanding ability to maintain and even out cosmetic products used with it. Due to capillary action,*1 cosmetic products are held firmly between both the layers of fibers and individual fibers, and liquid products are quickly and evenly distributed throughout the entire membrane. At the same time, excess water vapor can escape from the spaces between the interwoven fibers. As a result, the film is able to maintain adequate moisture permeability without completely blocking the skin.

Fine fiber technology can dramatically advance the endurance and evenness of cosmetic products on the skin's surface. This has been a great challenge over the years. Kao is looking forward to using its fine fiber technology in combination with its various cosmetics products to go beyond traditional concepts in skincare and makeup.

-

* 1 Capillary action: The ability of a liquid to flow between narrow spaces due to forces of attraction

The mechanisms behind fine fiber technology

The newly developed fine fiber technology uses a superfine fiber-spinning technology called the electrospinning method (referred to below as the ES method). This is common in the non-woven fabric industry. The ES method is a technology for spraying a positively charged polymer solution onto the surface of a negatively charged target object. The stretched, string-like polymer solution, much like silk spun by a silkworm, is forcefully ejected from the nozzle of a specialized applicator. The many layers of the solution form a membrane on the surface of the target object. The resulting film becomes thinner toward its edges, allowing it to blend naturally with the skin and rendering its boundaries unnoticeable. Additionally, because there is only a small difference in level between the membrane and the skin, it will not come off easily.

In developing the fine fiber technology, efforts were made to create an ultra-thin membrane that is stable and fast forming in real-life conditions. Kao also succeeded in making a small applicator as well as establishing the optimum voltage and solution flow rate.

The circumstances behind fine fiber technology's development

Throughout this research process, Kao's comprehensive strength in non-woven fabric development for various business fields has been vital.

Kao has developed and applied non-woven fabrics with a variety of features for sanitary products and home care products. Examples include baby diapers, feminine care products, and cleaning wipes. In addition, in order to facilitate the development of next-generation non-woven fabrics, focus was placed on qualities such as capillary action, softness, and adhesion strength. All are affected by the fineness of the fibers. In 2007, work commenced on the development of an in-house ES device. During the research process, it was noticed that the fiber membrane had traits similar to that of the thin layer of skin (stratum corneum). From that, the idea of adapting the membrane for cosmetic uses emerged. After numerous efforts in joint research by several of Kao's special divisions—including machinery, electronics, materials, safety, and structural analysis—the new fine fiber technology was completed.

The future created by fine fiber technology

Kao is working to view daily life from the consumer's perspective and make technological innovations that contribute to the future of society. Kao will advance research and continue pursuing fine fiber applications in cosmetic products such as skincare and makeup items, while also considering adaptations of the technology for use in the therapeutic field.

About Kao

Kao creates high-value-added products that enrich the lives of consumers around the world. Through its portfolio of over 20 leading brands such as Attack, Bioré, Goldwell, Jergens, John Frieda, Kanebo, Laurier, Merries and Molton Brown, Kao is part of the everyday lives of people in Asia, Oceania, North America and Europe. Combined with its chemical division, which contributes to a wide range of industries, Kao generates about 1,500 billion yen in annual sales. Kao employs about 33,000 people worldwide and has 130 years of history in innovation. Please visit the Kao Group website for updated information.

Media inquiries should be directed to:

Corporate Communications

Kao Corporation