Technology for Keeping Makeup Beautiful

Makeup

Cosmetics users expect base makeup, such as makeup bases and foundations, and point makeup, such as eye shadow and lipsticks, to provide not only a beautiful finish but also to last all day long.

To keep base makeup looking beautiful, it is important to form a makeup coating film resistant to sweat and sebum, which are major causes of makeup smudges.

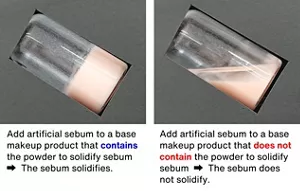

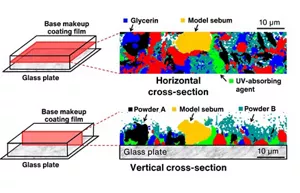

Kao is working to develop base makeup that does not shine and smudge by using a powder that selectively solidifies sebum (Figure 1) and our unique film-forming agent that creates a flexible film. We have also developed a method for analyzing the ingredients in a base makeup coating film (Figure 2) and an AI-based method for evaluating makeup smudges. We use these technologies to visualize the conditions of oily shine and smudging so we can refine the technologies for making makeup last longer.

Figure 1 The powder’s effect solidifies sebum

Figure 2 Analysis of the components within

the coating film using Raman spectroscopy

for base makeup

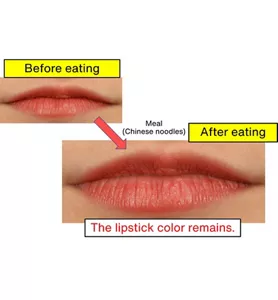

Lipsticks are smudged by talking, eating and drinking, wearing a mask and other physical contact, so it is important that the lips and lipstick adhere strongly to each other.

We used our unique gelatinizing agent to develop a long-lasting lipstick that gelatinizes by moisture after it is applied, and adheres firmly to the lips (Figure 3). We also use our unique polymers that allow stress to act (generate normal stress) on the lips when they are rubbed against each other (Figure 4)*1 to develop long-lasting lipsticks that feel thick and moist.

Figure 3 Evaluation of the long-lasting effect of the

lipstick, which uses our unique gelatinizing agent

Figure 4 Deformation and flow properties of

normal stress polymers

We will continue to work on the development of makeup products so we can bring beauty and smiles to people around the world.

-

* 1 Tamura, E., Ohsaki, K., Kuwahara, K., Nanbu, H., & Nabata, Y. (2016). Texture Control of the Lipstick Film Using Rheological Technique and Commercialization of Liquid Rouge. Nihon Reoroji Gakkaishi, 44(5), 231-236.

- Home

- Innovation

- Research & Development

- Product Development Research

- Make Up

- Technology for Keeping Makeup Beautiful

- Home

- Innovation

- Research & Development

- Product Development Research

- Make Up

- Technology for Keeping Makeup Beautiful