Foam Color Technology that Enables Everyone to Dye the Entire Hair Evenly and Beautifully with Ease

Hair Color

Hair coloring is popular with a wide range of age groups around the world because it satisfies our desire for a certain appearance, such as wanting to change hair color to give a cheerful impression or to dye gray hair to look younger. In other words, it helps us to affect the impression our appearance makes on others.

As for home-use hair coloring products, we have received requests from many customers for products that enable them to dye their hair evenly and easily on their own, without the need for advanced skills like those of a professional hairdresser.

To meet this demand, we focused on the properties of the “foam”, which has a large volume, softness, and is easy to apply and spread, and so embarked on the development of Foam Color.

Because foam-type hair coloring formulation development was unprecedented, the technological development posed significant challenges. However, leveraging Kao's accumulated knowledge in interface science cultivated over many years, we succeeded in creating a formulation that ensures hair dyeability, which is the fundamental function of hair colors, while also providing high foam stability to prevent dripping during the application period, as well as offering a high hair care effect that reduces hair stiffness and improves finger combability after dyeing.

Since its launch as Foam Color in 2007, it has been well-received as a range of user-friendly at-home hair color products.

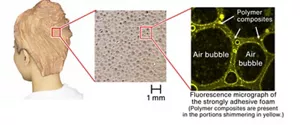

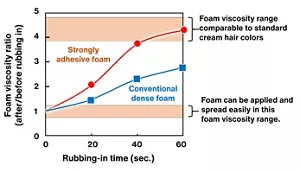

We have continued to develop this technology and steadily improved in in terms of user-friendliness and performance. The current version of Foam Color product features the introduction of our unique “Transformation Technology,” where the foam is easy to spread evenly throughout the hair during application, and when rubbed in after application, the polymer composites specifically adhere to the air-liquid interface, transforming into a highly adhesive foam similar to cream. This innovation has led to the evolution of a higher-performance Foam Color product. (Figures 1 and 2).

Figure 1 Strong adhesion of foam during dyeing

Figure 2 Relationship between rubbing-in time and foam viscosity

- Home

- Innovation

- Research & Development

- Product Development Research

- Hair Care

- Foam Color Technology that Enables Everyone to Dye the Entire Hair Evenly and Beautifully with Ease

- Home

- Innovation

- Research & Development

- Product Development Research

- Hair Care

- Foam Color Technology that Enables Everyone to Dye the Entire Hair Evenly and Beautifully with Ease