Fine-Fiber Manufacturing Technology

Molding Process

The Fine-Fiber (FF) technology developed by Kao can form ultra-thin membranes made of ultrafine fibers with a diameter of less than 1 um using electric power. These membranes are light, soft and adhere flexibly to the skin even when it deforms, smoothing the skin surface.

For example, when compared to fibers with a diameter of 100 µm, fibers with a diameter of 1 µm have a specific surface area 100 times larger, a capillary force 100 times greater, and are 100 million times softer. This means membranes made of these ultrafine fibers have completely different physical properties. Softer fibers form membranes that adhere much better to the skin, do not come off easily, and naturally fit the skin.

A higher capillary force makes it possible for membranes to retain a formulation in the fiber network for a long time. An ultrafine-fiber sheet (FF sheet) can be used in combination with a skin-care formulation to retain it in the FF sheet for extended periods and create an ideal moist environment on the skin.

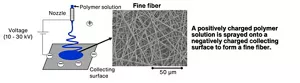

Kao has focused on electrospinning, a method for making ultrafine fibers by applying high voltage to a polymer solution, and has applied this method to develop a technology for manufacturing FF sheets. Although the conventional electrospinning method has low productivity which results in higher costs, we developed a technology that achieves both highly functional product and its productivity by controlling the physical properties of polymers to be spun and the electric fields.

In the future, we will apply this FF technology to various fields with the aim of providing customers with new value.

Electrospinning (ES) method

Structure of fine fibers on the skin

- Home

- Innovation

- Research & Development

- Fundamental Research

- Production Technology

- Fine-Fiber Manufacturing Technology

- Home

- Innovation

- Research & Development

- Fundamental Research

- Production Technology

- Fine-Fiber Manufacturing Technology