Bioprocess Technology that Uses Microbes to Manufacture Aromatic Compounds from Biomass

Bio-conversion

Many of the chemicals that support our daily lives are manufactured from petroleum by chemical synthesis or by using extracts from rare plants.

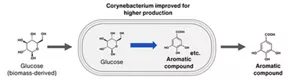

To use such chemicals sustainably, there is strong demand for manufacturing processes with low environmental load that uses biomass as renewable resource by a fermentation technology with microbes.

Aromatic compounds, which are a group of important chemicals, are difficult to produce efficiently by fermentation, and there have previously been few commercial aromatic compounds produced by bioprocesses. To produce aromatic compounds by fermentation, it is important to precisely control the oxygen concentration during fermentation in order to both maintain microbial activity and improve the product quality.

However, this is difficult to do in large industrial-scale facilities, as the oxygen concentration tends to be non-uniform in tanks.

Based on knowledge about bioprocess technologies we have accumulated over years through production of enzymes for detergents and bases for cosmetics and hair-care products as well as technologies for simulating and visualizing tank environments, Kao developed a technology for producing aromatic compounds efficiently by fermentation on an industrial scale.

By applying this manufacturing technology, we have started industrial production of gallic acid as an aromatic product that is made from biomass. It is used in a wide range of applications such as boiler rust inhibitors and raw materials for semiconductor circuits.

In the future, we plan to produce aromatic compounds other than gallic acid by fermentation, with the aim of providing products and solutions that solve problems facing customers, the environment, and industries to the world.

Related Information

- Home

- Innovation

- Research & Development

- Fundamental Research

- Production Technology

- Bioprocess Technology that Uses Microbes to Manufacture Aromatic Compounds from Biomass

- Home

- Innovation

- Research & Development

- Fundamental Research

- Production Technology

- Bioprocess Technology that Uses Microbes to Manufacture Aromatic Compounds from Biomass