Evolution of Cellulose Derivatives

Polymer

Plant-derived Cellulose, which does not cause resource depletion (is not from a fossil fuel) and does not increase carbon dioxide emissions when used, has been attracting attention. In light of this, Kao has been developing new raw materials using Cellulose (Cellulose derivatives) and technologies for manufacturing them. Recently, we have created the Cellulose derivatives AC-HEC and C-HPC, which are important raw materials that give Kao’s products ease of use and high performance.

AC-HEC is used as a raw material for laundry detergents. Previously, surfactants were added to detergent to help making clothing ‘clean’. With AC-HEC, detergents are now able to not only ‘clean’ but an ‘easy to shed’ functionality has been added.

C-HPC is used as a raw material for shampoos. It stabilizes foam and increases its volume, and also has the effect of spreading the oil ingredients in the shampoo evenly over hair and making it manageable.

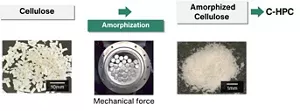

In our manufacturing processes, we strive to minimize CO2 emissions by reducing the amounts of energy and raw materials used. Especially in the process of manufacturing C-HPC, we apply an amorphization technology that breaks hydrogen bonds by physical force to manufacture a homogeneous derivative from Cellulose with low reactivity — In addition, by setting conditions based on the diffusion and reaction speed of the reactant, we have been able to significantly reduce the amounts of solvent and reactant used.

Technology for manufacturing C-HPC –amorphization

Kao develops production technologies based on chemical and engineering perspectives in order to improve the functionality and performance of our products and reduce their environmental impact.

- Home

- Innovation

- Research & Development

- Fundamental Research

- Material Science

- Evolution of Cellulose Derivatives

- Home

- Innovation

- Research & Development

- Fundamental Research

- Material Science

- Evolution of Cellulose Derivatives