Sustainable Surfactant Bio IOS and Precise Oil Conversion Technology

Material Development

Surfactants that use sustainable raw materials are necessary to maintain cleanliness in peoples’ lives. So at Kao, we have developed the sustainable surfactant Bio IOS, which uses fatty oil containing long alkyl chains as a raw material. While it is abundantly available, it has only been used for limited purposes to date.

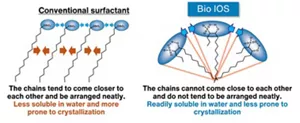

Unlike conventional surfactants, Bio IOS has a unique structure that has a hydrophilic (water-attracting) group in the middle of the alkyl chain (Figure 1). This structure makes the surfactant with long alkyl chains, which are usually poorly soluble, highly soluble in water.

Figure 1 Unique structure and characteristics of Bio IOS

Bio IOS is made from internal olefin derived from fatty alcohol. To achieve stable and high-volume production of Bio IOS, our expert researchers in the two separate fields of material science and production technology have worked on the development of various technologies in collaboration with one another.

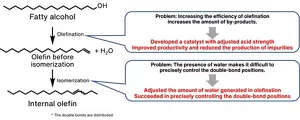

We used a catalyst with uniquely adjusted acid strength to convert fatty alcohol into olefin (olefination), improving productivity while reducing the production of by-products. We also precisely controlled the double-bond positions in internal olefin by adjusting the amount of water generated in the process of olefination (Figure 2).

Figure 2 Development of technologies for manufacturing internal olefin, the intermediate material for Bio IOS

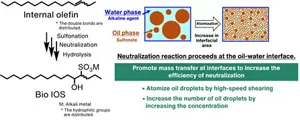

We also developed a unique reactor structure in the process of the sulfonation reaction for converting internal olefin into Bio IOS. By using inert gas in the reactor structure to control the reaction, we realized a favorable color quality. In the following neutralization process, we controlled the production of impurities by applying high-speed shearing technology used for emulsification (Figure 3).

Figure 3 Neutralization promotion technology in manufacturing Bio IOS

These technologies from Kao now enable us to supply Bio IOS in a stable manner and use it in the liquid laundry detergent Attack ZERO series and other products. We aim to help bring about a sustainable society through producing and selling Bio IOS both in Japan and abroad.

Attack ZERO series containing Bio IOS

This article is related to material science and is re-posted with a new title.

Related Information

- Home

- Innovation

- Research & Development

- Fundamental Research

- Material Science

- Sustainable Surfactant Bio IOS and Precise Oil Conversion Technology

- Home

- Innovation

- Research & Development

- Fundamental Research

- Material Science

- Sustainable Surfactant Bio IOS and Precise Oil Conversion Technology