- Kao Thailand

- News Release

- News Release 2024

- Introducing 'NEWTLAC': Kao's Eco-Friendly Innovation in Road Construction, transforming Plastic Bottles into the Roads of Tomorrow

Introducing 'NEWTLAC': Kao's Eco-Friendly Innovation in Road Construction, transforming Plastic Bottles into the Roads of Tomorrow

"Imagine a future where plastic bottle waste in Thailand is significantly reduced, thanks to an innovative solution that transforms it into roads."

In an era where infrastructure is deteriorating due to prolonged use and the road construction industry faces environmental challenges, Kao Industrial (Thailand) Co., Ltd., or Kao, a leading manufacturer of consumer products and chemicals from Japan has developed "NEWTLAC", a cutting-edge innovation that combines a special polymer with asphalt for road construction. NEWTLAC not only addresses

waste issues but also creates stronger, more durable roads, revolutionizing Thailand's road construction industry. Pilot projects have been launched on roads in Amata City Chonburi Industrial Estate and Bangkok's Min Buri district.

Kao Chemicals: Enhancing Quality of Life

While many may know Kao for its household products, which have been a staple in Thai homes for over 60 years – such as Attack detergent, Haiter bleach, and Laurier sanitary napkins – the company also has Chemicals Business. This division supplies a wide range of chemicals across various industries, including agriculture, construction, utilities, foundries, plastics, rubber, and more. Kao Thailand is not only a research and development hub but also a fully integrated production center, delivering high-quality, efficient chemical products. These chemicals are part of the supply chain for numerous consumer goods, meeting customer needs across various sectors.

From Plastic Bottles to High-Quality Roads

NEWTLAC is a sustainable product from Kao Chemicals that enhances the quality of asphalt by incorporating recycled PET plastic bottles. Through a chemical process, used PET bottles are transformed into a fine yellow powder like granulated sugar, which is then mixed with regular asphalt. The result is a special type of asphalt that boasts exceptional strength and durability, superior water erosion resistance, and a longer lifespan.

According to research by Kao Corporation in Japan, constructing roads with NEWTLAC can recycle up to 1,430 PET bottles for every 100 square meters of road. Moreover, this NEWTLAC-infused asphalt not only matches or surpasses the performance of traditional Polymer Modified Asphalt (PMA) but also contributes to environmental solutions by reducing fine particle emissions from asphalt. This helps to reduce air pollution and address the global plastic bottle waste crisis. It is considered to effectively add value to plastic waste and reduce its environmental impact.

Turning Theory into Tangible Success in Practice

Recently, NEWTLAC has been put into practical use in 2 significant areas including Amata City Industrial Estate, Chonburi Province, where 140 kilograms of NEWTLAC were used to cover a 500-square-meter area

in front of Kao's factory. Also, the Nimit Mai Intersection in the Min Buri District of Bangkok, where 180 kilograms of NEWTLAC were used to pave a 750-square-meter area. It is also currently being tested at Chiang Mai University, marking an important step in the continued development of Kao's sustainable and environmentally friendly infrastructure.

Image of road paving with NEWTLAC in Amata City Industrial Estate, Chonburi

Image of road paving with NEWTLAC at Nimit Mai Intersection, Min Buri District, Bangkok.

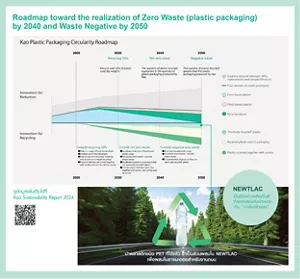

A Future of Sustainable Development with a "Zero Waste" Goal

Since 2020, Kao has achieved zero landfill waste at its production facilities in Thailand, with nearly 100% of waste being recycled. This milestone is part of Kao's broader goal to reduce plastic waste in Thailand.

By 2027, the company aims to ensure that 100% of its packaging is recyclable.

NEWTLAC from Kao is more than just a road construction innovation; it is a key component of the company's long-term vision to minimize environmental impact. Kao is committed to achieving sustainability by 2040, with the goal of mitigating the impact of global warming. The company aims to reach net-zero carbon dioxide emissions and achieve zero waste from plastic packaging. This means the amount of plastic used in packaging will equal the amount of plastic recycled. Therefore, NEWTLAC exemplifies this success by using recycled PET plastic bottles for road construction, thus reducing plastic waste and advancing the development of high-quality infrastructure. This initiative is a crucial step toward building a sustainable society for future generations.

For more information, please contact Corporate Communications

Kao Industrial (Thailand) Co., Ltd.

O-NES Tower, 14th floor, 6, Soi Sukhumvit 6, Klongtoey Sub-District,

Klongtoey District, Bangkok 10110

Contact person: Corporate Communications

- Kao Thailand

- News Release

- News Release 2024

- Introducing 'NEWTLAC': Kao's Eco-Friendly Innovation in Road Construction, transforming Plastic Bottles into the Roads of Tomorrow